| |

|

| The goal of the Really Rapid Replicator project was to create a 3-D printing system that was fully automated, creating a prototype or replica of an object with one touch of a button. Our project used a camera setup to photograph an object and a mill to recreate it. We programmed all of the software, including the motor controls, PID algorithm, and vision. |

|

|

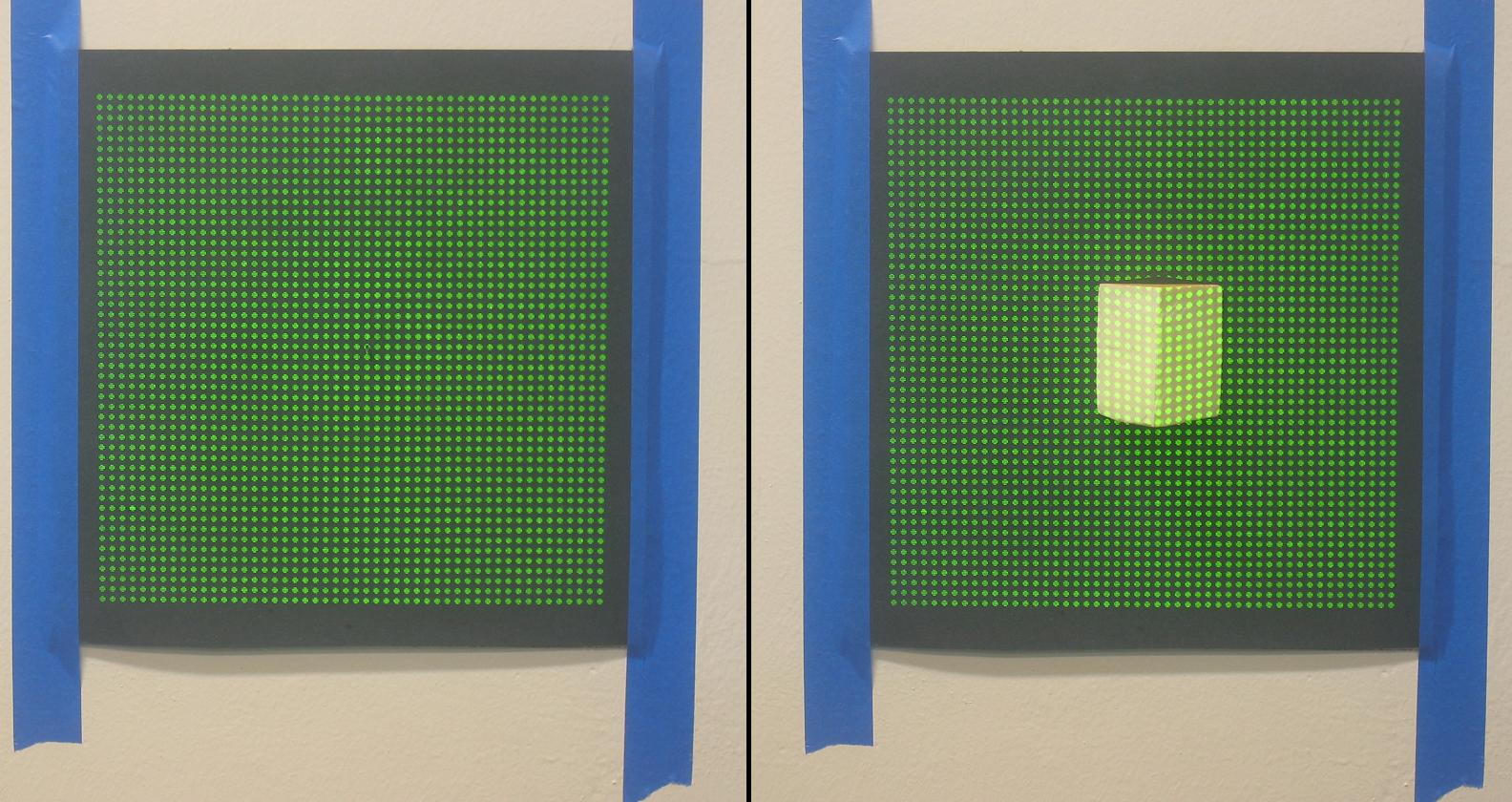

These two images make up a sample of the data inputed into the vision algorithm. To produce the images, a grid of green dots is projected on the imaging surface, and an image is taken with the object on the surface, as well as a calibration image without the object. |

|

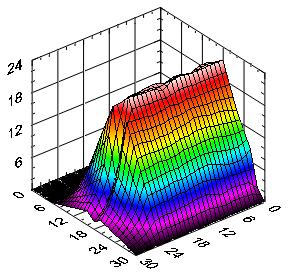

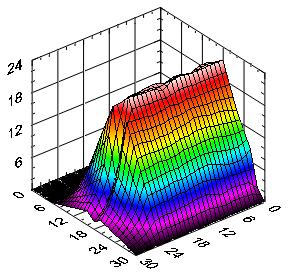

| The basic principle behind the vision algorithm is as follows: The camera's line of sight is at an angle with the projector's line of site. When the projected dots hit a surface that is closer to the camera than the calibration surface, the dots are shifted in the picture an amount which is proportional to the difference in this distance. Each projected dot is analyzed in the two pictures taken to find their displacements when the object is present. After some calibration adjustments, this information provides the height of the object at each grid point. The graph displayed here is a surface plot of the height information obtained after running the algorithm for the above pictures. |

|

|

|

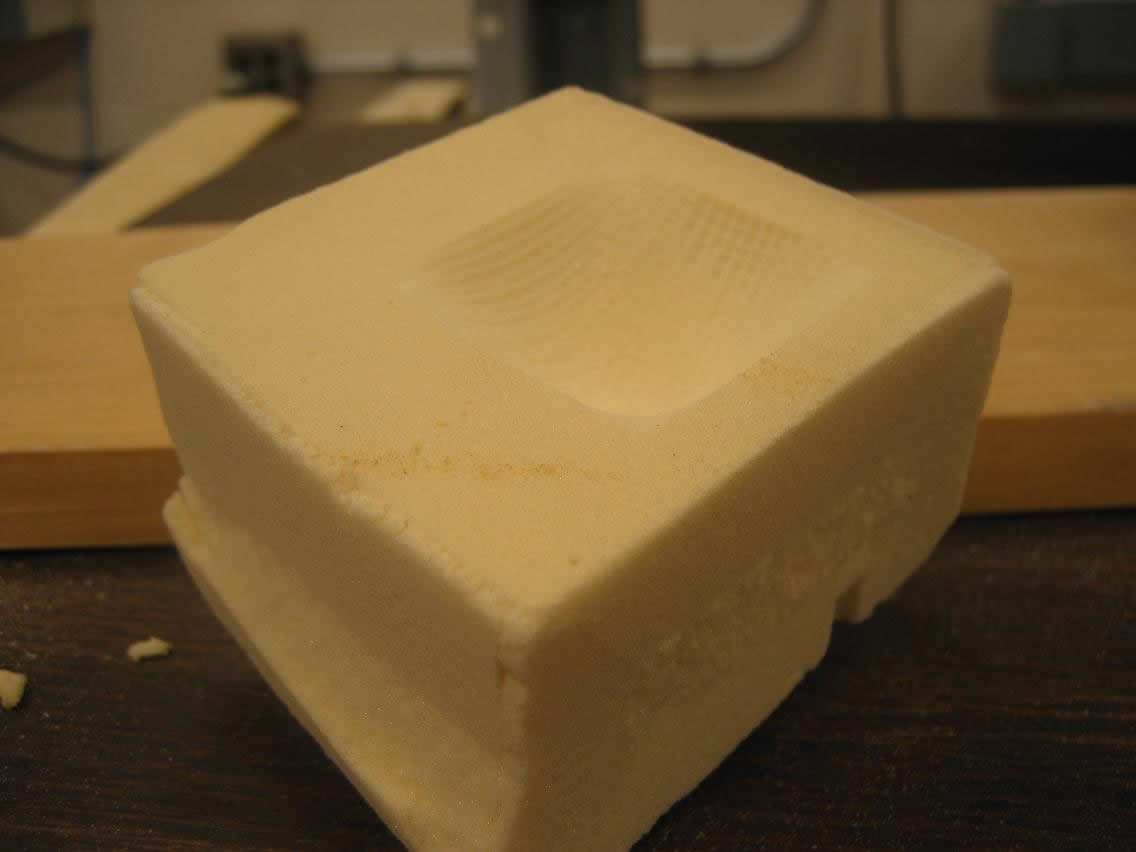

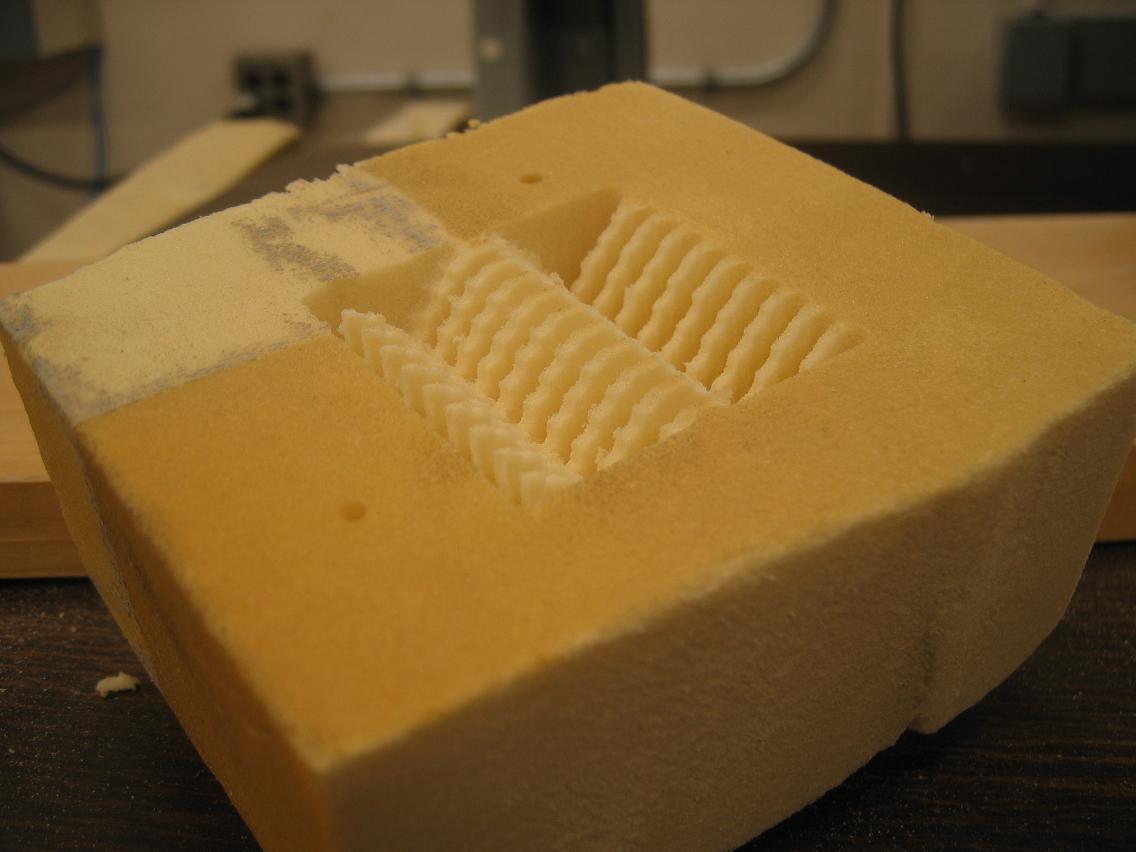

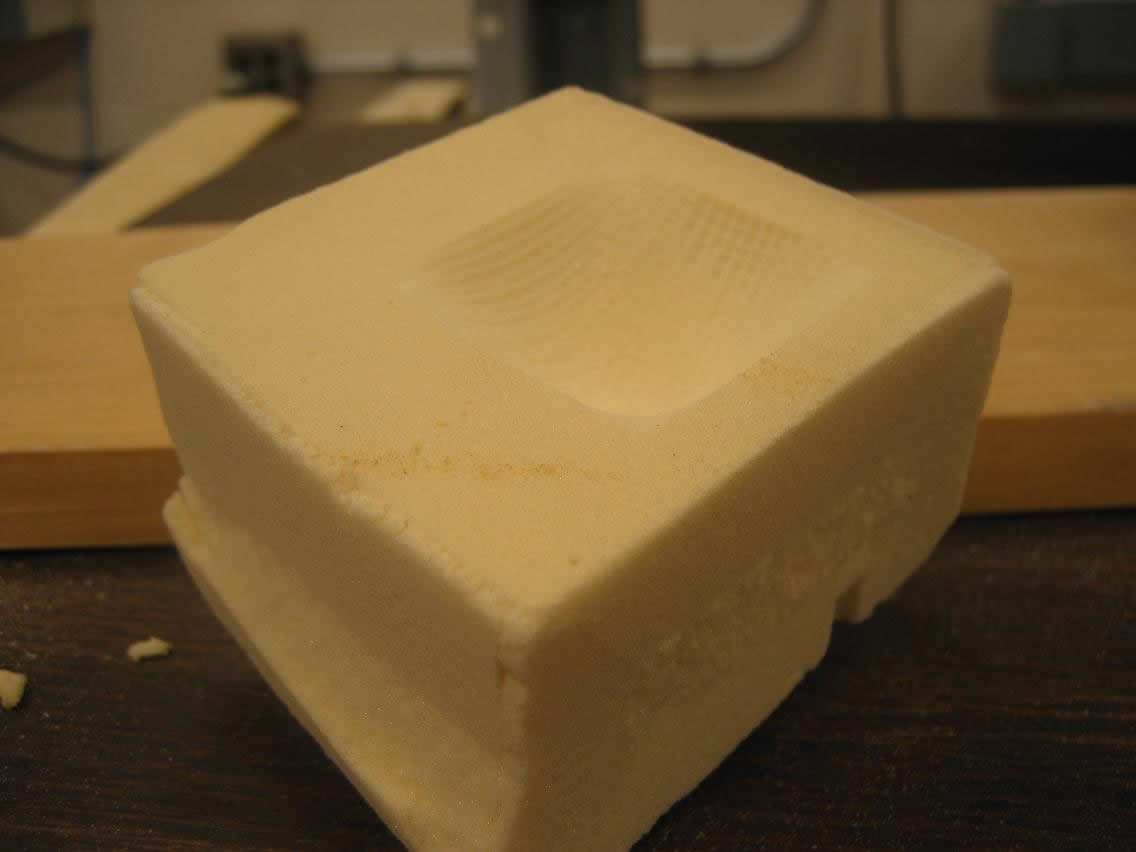

Here is the final result of the process. On the left is the original object and on the right is the object milled by our system. You can see from this picture that the process was a success. There are some visible ridges in the milled object that are due to the drill bit size and the process parameters, which were optimized for speed. At this speed the process was complete in a matter of seconds, and high quality objects can be milled within a few minutes. This system is easily scalable, and with more sophisticated hardware as well as more time for software development (we only had 6 weeks!) we are confident that we could create a system that can reproduce complicated objects very quickly. |

|

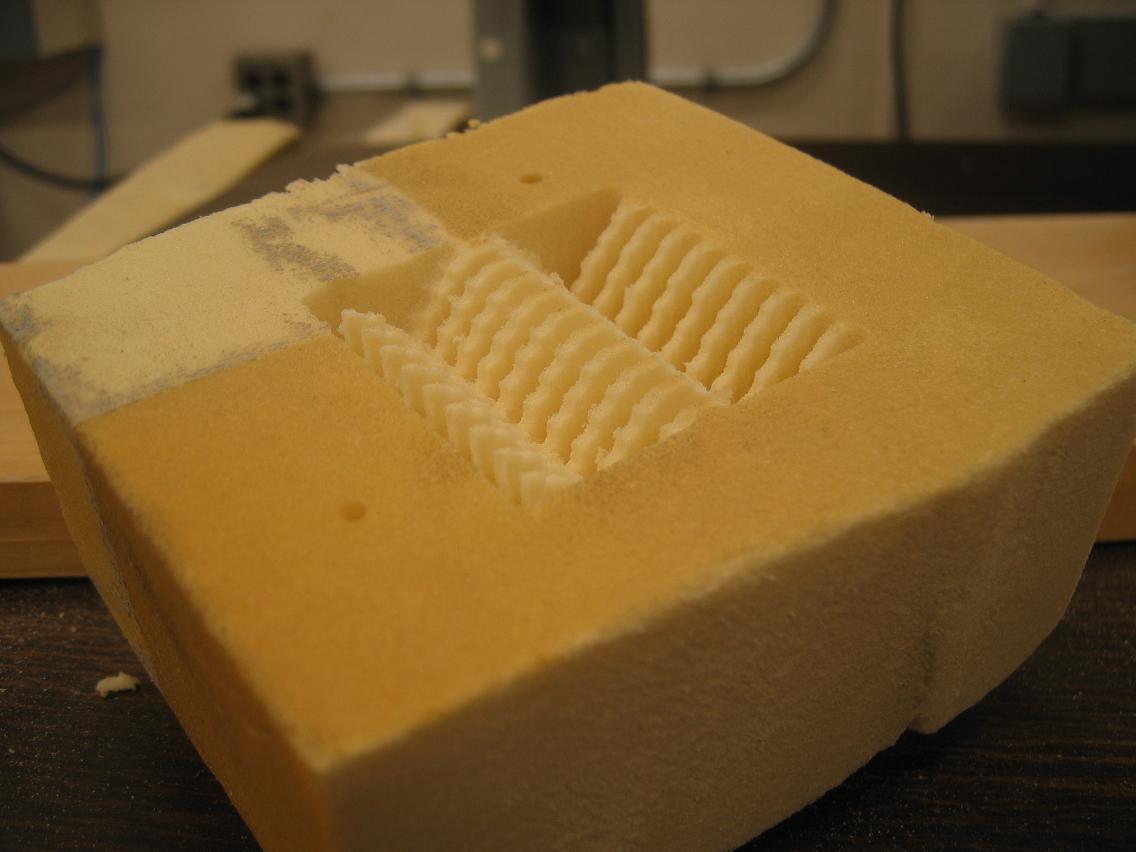

We also milled these objects without the vision system to demonstrate the capabilities of our PID algorithm and motor controls, which we programmed ourselves. |

|

| For fun we also milled the CAL logo and etched it in acrylic, which is another interesting application of this system. |

|

Group Members: |

|

David Chen, Mechanical Eng '08 |

Richard Fabini, Mechanical Eng '08 |

Kavon Hooshiar, Mechanical Eng '08 |

|