Overview

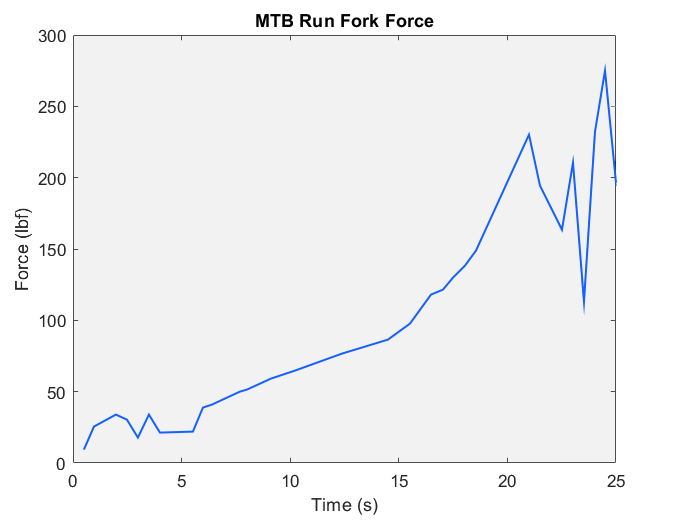

Perfomance bikes minimize weight. Minimizing weight entails running FEA on the design. Running FEA necessitates accurate load cases or a high FOS. Our bike FEA has always been limited by our estimated load cases.

Enter telemetry!

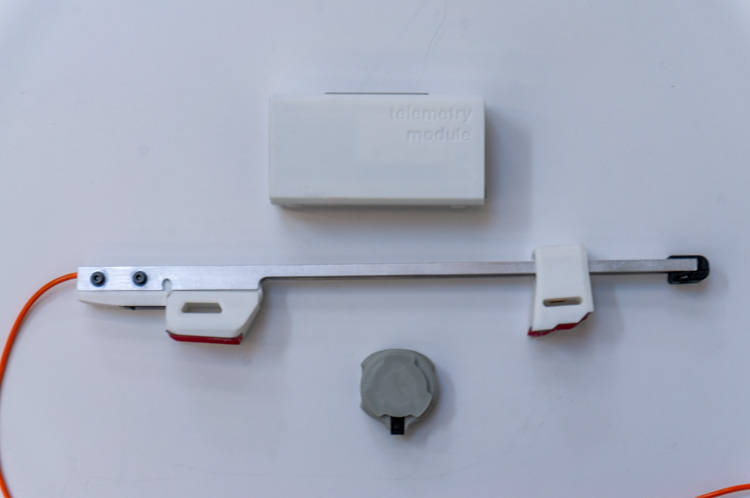

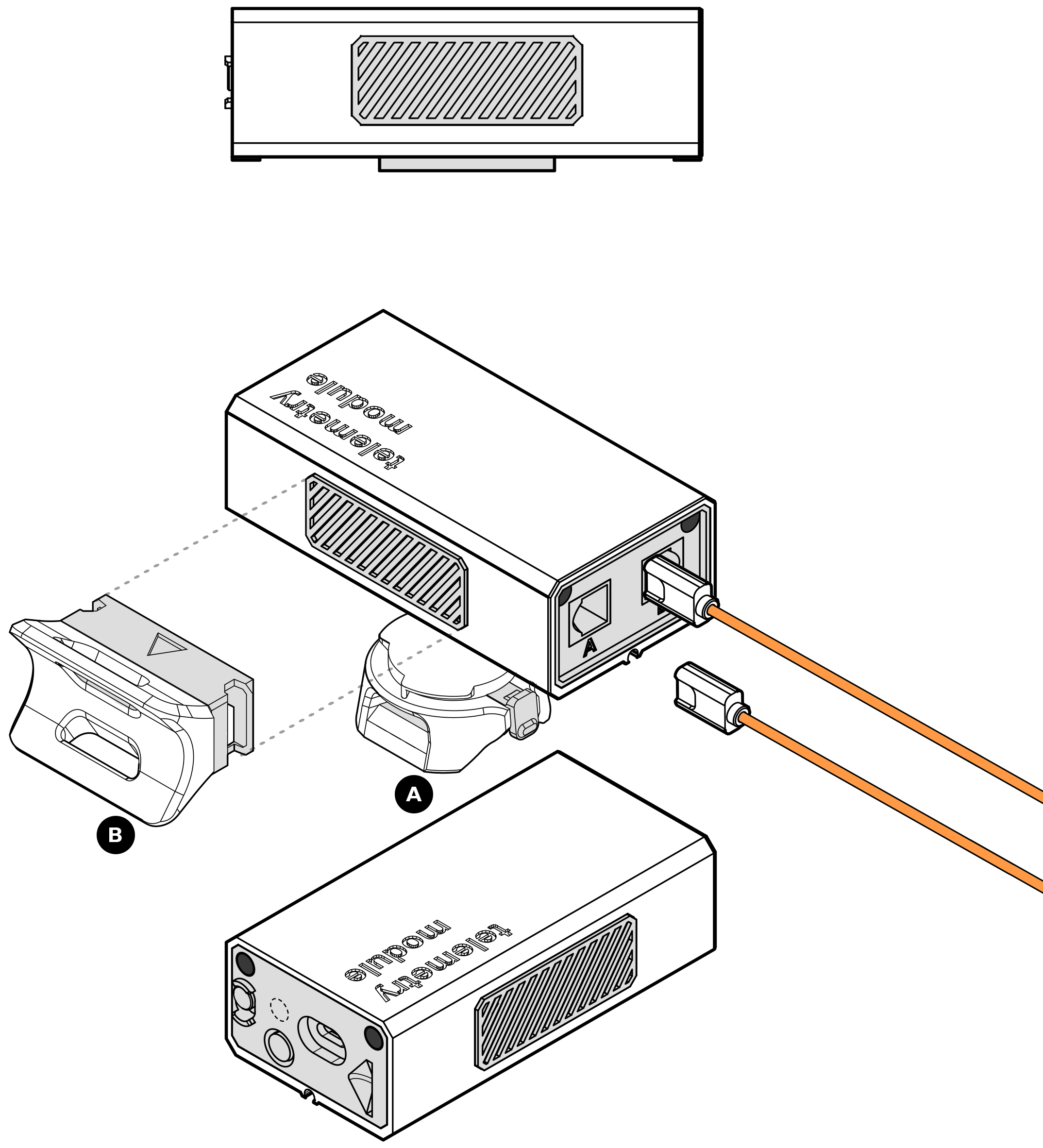

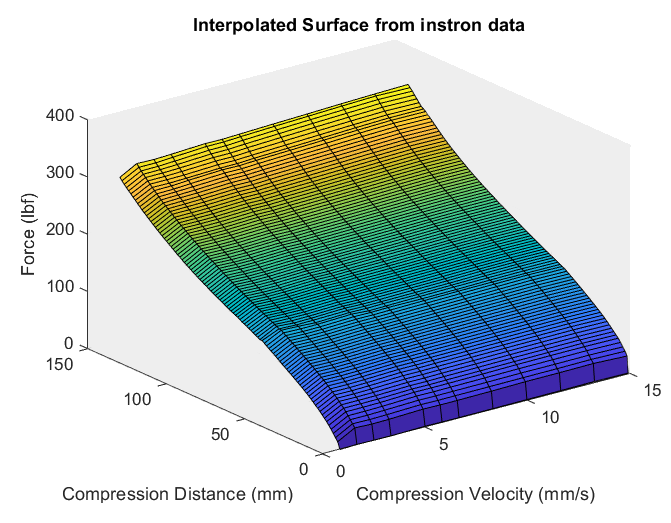

We developed a custom telemtry solution to record fork and shock compression, and then map it to a force/position/rate curve. The result is a force/time graph that we can use to calculate an accurate max force as well as fatigue estimates.

.png)